2200# and 2500# Zenair Floats

Dear Zenair,

The wheels are installed on my 2200 Zenair Floats and I have a few landings on them. My impression so far is two thumbs way up!!! They look like real brutes, but are nice and smooth taxiing and rolling out. With those two big AN bolts taking the load, they are a huge improvement over my previous set-up. I really don't anticipate any issues with these; will soon be landing on some smooth local grass strips. I think you guys nailed the problem, and I gotta say again how much I appreciate the time, effort and $$$ you guys spent addressing my issues. Russ S. (July 2012)

The wheels are installed on my 2200 Zenair Floats and I have a few landings on them. My impression so far is two thumbs way up!!! They look like real brutes, but are nice and smooth taxiing and rolling out. With those two big AN bolts taking the load, they are a huge improvement over my previous set-up. I really don't anticipate any issues with these; will soon be landing on some smooth local grass strips. I think you guys nailed the problem, and I gotta say again how much I appreciate the time, effort and $$$ you guys spent addressing my issues. Russ S. (July 2012)

2200#, 2500# Zenair Floats

Since bringing float production back to Canada (see History), Zenair has re-designed and improved its larger 2200# and 2500# floats. These two floats sizes are very similar and use identical parts for the wheels/gear and hydraulic system. The main difference between these floats is in the depth of the bulkheads which changes the buoyancy of the floats.

Main wheel tires are MASSIVE at 18.5" diameter and 600x6 wheel hubs are used for both float sizes. Nose wheel tire is 10" in diameter. The design loads for the 2500# floats were based on FAR23, so the lighter floats (i.e. the 2200#) are overbuilt and extra tough. Performances, rigging, etc. are very similar to typical certified floats.

Features that make Zenair floats outstanding include: wheels and gear size, light weight aluminum construction, easy assembly....and yes, they are remarkably affordable!

Main wheel tires are MASSIVE at 18.5" diameter and 600x6 wheel hubs are used for both float sizes. Nose wheel tire is 10" in diameter. The design loads for the 2500# floats were based on FAR23, so the lighter floats (i.e. the 2200#) are overbuilt and extra tough. Performances, rigging, etc. are very similar to typical certified floats.

Features that make Zenair floats outstanding include: wheels and gear size, light weight aluminum construction, easy assembly....and yes, they are remarkably affordable!

Special features of the straight floats:

- Lightweight and very strong

- 6061-T6 aluminum - Top skin thickness is 0.032", and bottom front skin thickness is 0.040".

- All bulkheads are made of 0.032" 6161-T6 aluminum

- 3/4"x3/4"x1/8" extrusions are riveted to the bottom sides of the floats. Same extrusions are also riveted to the center of the front bottom skins.

- Top walkway area is +8.5" wide making it easy to walk on the floats.

- Fiberglass tips

- Extruded aluminum keel

- Easy to install spreader bar system for floats

- Use of a 3M Marine Adhesive Sealer seals the floats but also adds to overall strength

- We recommend the use of special sealed pulled-rivets (included in the kits), but standard solid rivets can be substituted. Using the pulled (blind) rivets will speed up the building process by more than 50%. Note that in all cases, standard solid rivets are used on the extrusions and the keel so as to maximize strength.

- Lightweight and very strong

- 6061-T6 aluminum - Top skin thickness is 0.032", and bottom front skin thickness is 0.040".

- All bulkheads are made of 0.032" 6161-T6 aluminum

- 3/4"x3/4"x1/8" extrusions are riveted to the bottom sides of the floats. Same extrusions are also riveted to the center of the front bottom skins.

- Top walkway area is +8.5" wide making it easy to walk on the floats.

- Fiberglass tips

- Extruded aluminum keel

- Easy to install spreader bar system for floats

- Use of a 3M Marine Adhesive Sealer seals the floats but also adds to overall strength

- We recommend the use of special sealed pulled-rivets (included in the kits), but standard solid rivets can be substituted. Using the pulled (blind) rivets will speed up the building process by more than 50%. Note that in all cases, standard solid rivets are used on the extrusions and the keel so as to maximize strength.

Float Size |

Weight per Float |

Length |

Max. Width |

Standard Kit |

#2200 Straight |

110 lbs |

17. 5 feet |

32.5" |

Available |

#2200 Amphibious |

160 lbs |

17. 5 feet |

32.5" |

Available |

#2500 Straight |

115 lbs |

17. 5 feet |

34" |

Available |

#2500 Amphibious |

165 lbs |

17. 5 feet |

34" |

Available |

Float weights are approximate and includes the wheels/brakes in amphibious models. Weight does not include Rigging / Spreader bars kit or hydraulic pump, paint and/or other optional equipment. For fuselage mounting hardware, contact the airframe manufacturer.

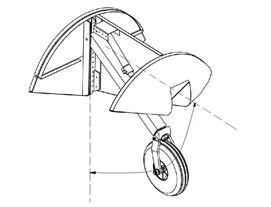

Amphibious nose wheel details:

- Free castering wheel.

- Heavy duty 2"x2" extruded aluminum arm moves the wheels up & down.

- Grease fittings installed at wheel rotating system and at axle for low wear.

- Nose wheel hubs are sealed bearings and treated aluminum.

- Tires are extra large at 10” diameter.

- Stainless steel hydraulic cylinders moves the wheels up & down

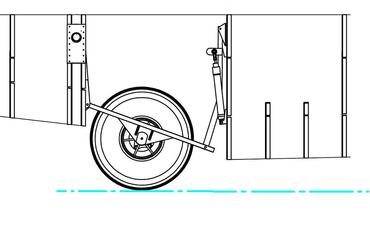

Amphibious main wheel details:

- 600x6 heavy duty hub with brakes.

- Tire used is extra large at 18.5” diameter, making it the best floats for grass strip landings.

- Hub system is anodized A356 aluminum.

- Watertight lip seals are used in place of normal felt seals.

- Grease retainer installed between wheel halves.

- Mechanical system locks wheels in the down position and therefore does not stress the hydraulic system on hard landings.

- Hydraulic cylinders moves the wheels up & down.

- Gear system is connected to 2 bulkheads for extra strength. Bulkheads are 0.032 thick aluminum and reinforced with 11/2"x1"x1/8” thick extrusions.

- Hydraulic system is operated by either an electric hydraulic and/or mechanical pump system.

- The compact electric unit is completely self-contained with motor, gear pump, reservoir, internal valving, load hold checks and relief valves. Electric motor uses 20 amp for only a few seconds.

- The electrically powered unit weight is about 6 lbs and can be installed just about anywhere in the fuselage which can aid in establishing proper CG position. Power unit is operated by a 3 way switch mounted on the instrument panel. 2 flexible high pressure nylon type hoses run from the pump to each float.

- The mechanical pump has an external hydraulic oil reservoir and does require more time to install. The pump is typically mounted in front of the pilot seat for easy pumping with reservoir in the rear fuselage. Weight is the same as the electric system and same high pressure nylon lines are used. Both systems have a pressure relief valve as to not put too much pressure in the system.

- 600x6 heavy duty hub with brakes.

- Tire used is extra large at 18.5” diameter, making it the best floats for grass strip landings.

- Hub system is anodized A356 aluminum.

- Watertight lip seals are used in place of normal felt seals.

- Grease retainer installed between wheel halves.

- Mechanical system locks wheels in the down position and therefore does not stress the hydraulic system on hard landings.

- Hydraulic cylinders moves the wheels up & down.

- Gear system is connected to 2 bulkheads for extra strength. Bulkheads are 0.032 thick aluminum and reinforced with 11/2"x1"x1/8” thick extrusions.

- Hydraulic system is operated by either an electric hydraulic and/or mechanical pump system.

- The compact electric unit is completely self-contained with motor, gear pump, reservoir, internal valving, load hold checks and relief valves. Electric motor uses 20 amp for only a few seconds.

- The electrically powered unit weight is about 6 lbs and can be installed just about anywhere in the fuselage which can aid in establishing proper CG position. Power unit is operated by a 3 way switch mounted on the instrument panel. 2 flexible high pressure nylon type hoses run from the pump to each float.

- The mechanical pump has an external hydraulic oil reservoir and does require more time to install. The pump is typically mounted in front of the pilot seat for easy pumping with reservoir in the rear fuselage. Weight is the same as the electric system and same high pressure nylon lines are used. Both systems have a pressure relief valve as to not put too much pressure in the system.

Rivets:

In order to maximize the strength of the floats, extrusions are solid riveted with typical AN aluminum type rivets. For customer who really do not want to solid rivet the floats together, Zenair can supply a stainless steel rivet designed for maximum strength but also for water sealing.

In order to maximize the strength of the floats, extrusions are solid riveted with typical AN aluminum type rivets. For customer who really do not want to solid rivet the floats together, Zenair can supply a stainless steel rivet designed for maximum strength but also for water sealing.

Pumps:

Two high quality hydraulic units are available. Both are compact and lightweight (at 6.5 lbs for electric; 2.5 lbs for manual). The oil tank of the electric unit (left in above photo) is easy to inspect and to fill. Both systems have pressure release valves to make sure that the hydraulic system does not become overloaded. When ordering your floats, specify which unit you want.

Two high quality hydraulic units are available. Both are compact and lightweight (at 6.5 lbs for electric; 2.5 lbs for manual). The oil tank of the electric unit (left in above photo) is easy to inspect and to fill. Both systems have pressure release valves to make sure that the hydraulic system does not become overloaded. When ordering your floats, specify which unit you want.

NOTICE: If you are considering Zenair Floats for a Type-Certificated aircraft (NOT EXPERIMENTAL), please read the Q&A.

Weights are approximate and

includes the wheels/brakes and hydraulics on the floats. Weight does not

include Rigging/Spreader bars kit, hydraulic pump mounted in aircraft,

paint or other optional equipment. All information is approximate and

subject to change without notice.