1450# Zenair Float

Available as straight or amphibious floats. These floats were especially designed for LSA and SLSA manufacturers.

Special features:

Special features:

- Easy to install spreader bar system to floats

- Use of a 3M Marine Adhesive Sealer for sealing the floats but also adds to the overall strength

- We recommend the use of special sealed pulled-rivets (included in kits), but standard solid rivets can be substituted. Using the pulled (blind) rivets will speed up the building process by more than 50%.

ZENAIR FLOATS |

Weight per float |

Length |

Max. Width |

Standard Kit |

#1450 Straight |

60 lbs |

15.5 feet |

27" |

Available |

#1450 Amphibious |

100 lbs |

15.5 feet |

27" |

Available |

Float weights are approximate and includes the wheels/brakes in amphibious models. Weight does not include Rigging / Spreader bars kit or hydraulic pump, paint and/or other optional equipment. For fuselage mounting hardware, contact the airframe manufacturer.

|

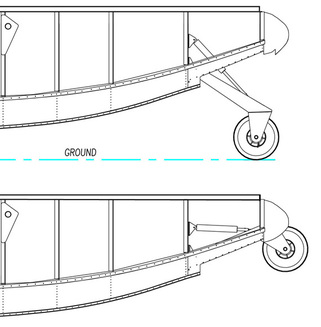

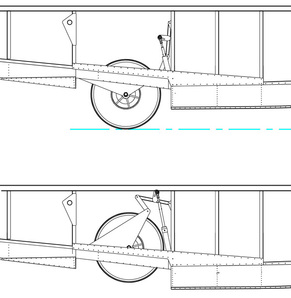

Amphibious nose wheel details:

- Free castering wheel with self centering spring system. - Heavy duty 3/16” aluminum arm moves the wheels up & down. - Grease fittings installed at wheel rotating system and at axle for low wear. - Nose wheel hub is manufactured by Grove, sealed bearings and treated aluminum hub. - Tire is extra large at 9” diameter. - Hydraulic cylinders moves the wheels up & down |

Amphibious main wheel details:

- 500x5 heavy duty hub with brakes.

- Hub system is anodized A356 aluminum.

- Watertight lip seals are used in place of normal felt seals.

- Grease retainer installed between wheel halves.

- Tire used is extra large at 14” diameter, making it the best floats for grass strip landings.

- Mechanical system locks wheels in the down position and therefore does not stress the hydraulic system on hard landings.

- Hydraulic cylinders moves the wheels up & down.

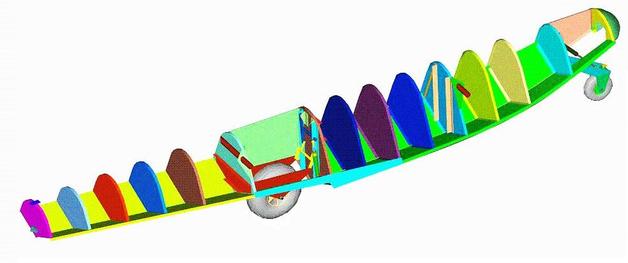

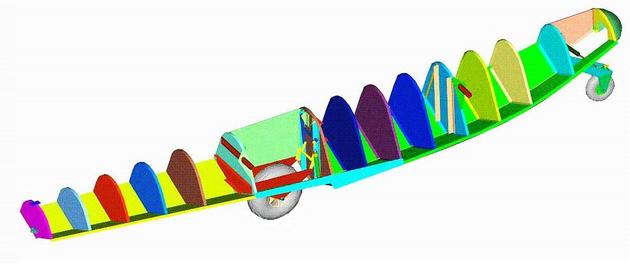

- Gear system is connected to 2 bulkheads for extra strength. Bulkheads are 0.032 thick aluminum and reinforced with 1/8” thick extrusions.

- Standard hydraulic system is operated by an electric pump (supplied in kit).

- The compact electric unit is completely self-contained with motor, gear pump, reservoir, internal valving, load hold checks and relief valves. Electric motor uses 20 amp for only a few seconds.

- The electrically powered unit weight is about 6 lbs and can be installed just about anywhere in the fuselage which can aid in establishing proper CG position. Power unit is then operated by a 3 way switch mounted on the instrument panel. 2 flexible high pressure nylon type hoses run from the pump to each float.

- Most mechanical pumps have an external hydraulic oil reservoir and require more time to install. Such pumps are typically mounted in front of the pilot seat for easy pumping action with the reservoir in the rear fuselage (not available from Zenair).

- 500x5 heavy duty hub with brakes.

- Hub system is anodized A356 aluminum.

- Watertight lip seals are used in place of normal felt seals.

- Grease retainer installed between wheel halves.

- Tire used is extra large at 14” diameter, making it the best floats for grass strip landings.

- Mechanical system locks wheels in the down position and therefore does not stress the hydraulic system on hard landings.

- Hydraulic cylinders moves the wheels up & down.

- Gear system is connected to 2 bulkheads for extra strength. Bulkheads are 0.032 thick aluminum and reinforced with 1/8” thick extrusions.

- Standard hydraulic system is operated by an electric pump (supplied in kit).

- The compact electric unit is completely self-contained with motor, gear pump, reservoir, internal valving, load hold checks and relief valves. Electric motor uses 20 amp for only a few seconds.

- The electrically powered unit weight is about 6 lbs and can be installed just about anywhere in the fuselage which can aid in establishing proper CG position. Power unit is then operated by a 3 way switch mounted on the instrument panel. 2 flexible high pressure nylon type hoses run from the pump to each float.

- Most mechanical pumps have an external hydraulic oil reservoir and require more time to install. Such pumps are typically mounted in front of the pilot seat for easy pumping action with the reservoir in the rear fuselage (not available from Zenair).

The Zenair #1450 floats above are installed on a 2-seat Highlander kit aircraft. Says the owner: LOTS OF FUN!

Our standard quality hydraulic pumps are electrical, compact and lightweight (about 6 lbs). The oil tank of the unit is easy to inspect and to fill. The pump has pressure release valves to ensure that the hydraulic system does not become overloaded.

|

Testimonial & comments from a Kitfox Super 7 owner:

"We just had our 2nd season with the Kitfox 7 on your 1450 floats - cannot get enough of flying with it! ...Regarding the 1450 float size, I cannot see any reason why they would have to be bigger for the Kitfox Super 7 as so far my experience - even at gross weight of 1,550 lbs - was great! Bigger floats would add drag and I am not sure if they would improve anything on the water." Tom in B.C. |

Another Float Kit assembler who: "...couldn't be more pleased with [his] float-equipped Kitfox"

Weights are approximate and includes the wheels/brakes and hydraulics on the floats. Weight does not include Rigging/Spreader bars kit, hydraulic pump mounted in aircraft, paint or other optional equipment. All information is approximate and subject to change without notice.